Vacuum sanitisation

Following years of intense experimentation, AV Sanification has developed an innovative system for sanitising and deodorising objects and furnishings using ozone.

Since ozone is a gas, when it is sprayed directly onto objects it spreads onto the surfaces by enveloping them. However, despite being heavier than air, ozone cannot penetrate deep into the component materials. For example, natural and synthetic textile fibres which make up clothes, shoes, fabrics, mattresses and an extraordinary amount of other products. The effectiveness of the treatment can therefore be only partial, failing to reach the microorganisms that live in the deepest layers.

For this reason AV Sanification has devised an exclusive ozone treatment system which, thanks to its multifunction generators and specially designed accessories, sanitises and deodorises objects in a vacuum environment.

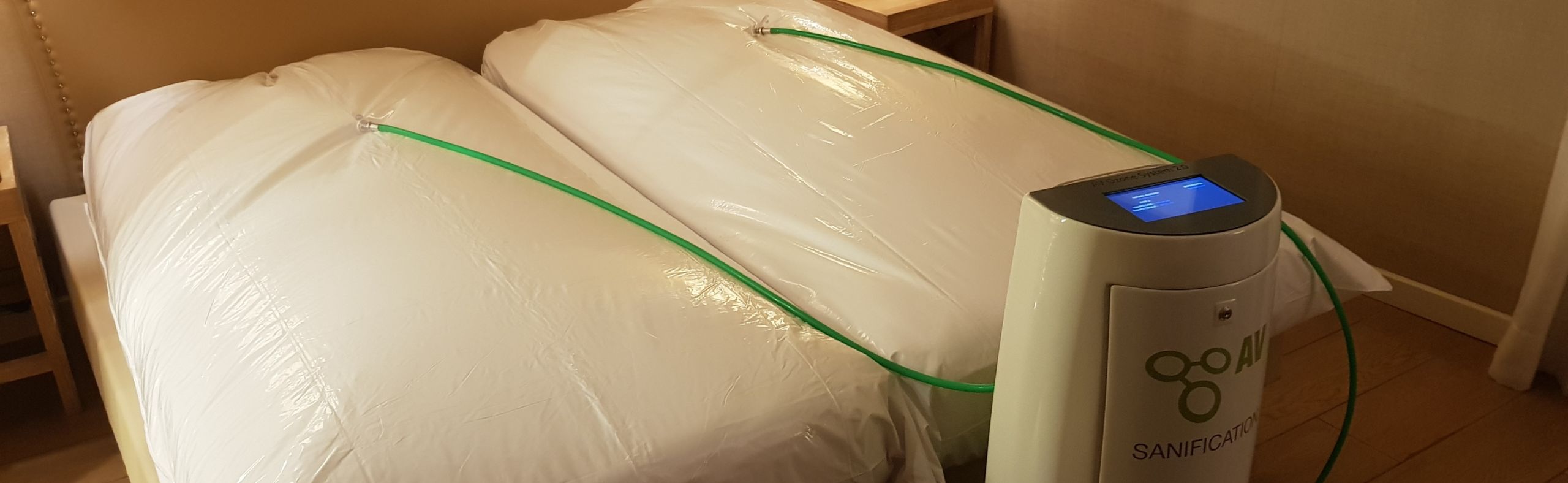

The objects to be sanitised are placed within special containers (boxes, cabins or PVC casings) specially designed together with the AV Sanification ozone generators. AV Sanification ozone generators are equipped with an air extraction pump that creates a vacuum inside the containers. The fibres composing the items are compressed, thus reducing in volume. At this point, ozone is slowly injected into the container so that the expanding fibres, like sponges, “suck” in the ozone. In this way the ozone penetrates completely inside the tissues, reaching and eliminating even the microorganisms present in the deepest points, guaranteeing complete sanitisation and deodorisation.

Once the saturation process is complete, the AV Sanification generator extracts the residual ozone, which is eliminated through special filters and again introduces air into the container. This avoids waiting for the time it takes for the natural conversion of ozone into oxygen, meaning that that the sanitised and deodorised objects are immediately ready for reuse only a few minutes after treatment.

AV Sanification’s ozone generators are equipped with control software that automatically manages all phases of the extraction-input-extraction process, ensuring optimal efficiency and safety of treatment.